|

|

|

|

|

公司簡介 公司簡介 |

|

聯絡資料 聯絡資料 |

|

公司地圖 公司地圖 |

|

產品與服務 (8) 產品與服務 (8)

| | 1. | 食品衛生級泵浦&溶混機系統&衛生級管件 Sanitary Pumps & Blending System | | | 2. | 莫諾式單螺桿推進腔泵 Progressive Cavity Pumps | | | 3. | 板式熱交換器系統 Plate Heat Exchanger System | | | 4. | 板式蒸發器&瞬間殺菌系統 Evaporators&Short-time Heating Sysytem | | | 5. | 殼管式鰭管式熱交換器 Shell & Tube HE | | | 6. | 特殊合金管件&衛生級拋光不銹鋼管件 Exotic Alloy & Sanitary Pipeworks | | | 7. | 石墨塊式熱交換器 Graphite Cylindrical & Cubic Block Heat Exchangers | | | 8. | 石墨殼管式熱交換器 Graphite Shell & Tube Heat Exchangers | | |

|

|

供需資訊 (0) 供需資訊 (0) |

|

部落格文章 (0) 部落格文章 (0)

|

|

總瀏覽人次 (25429) 總瀏覽人次 (25429) |

|

|

|

|

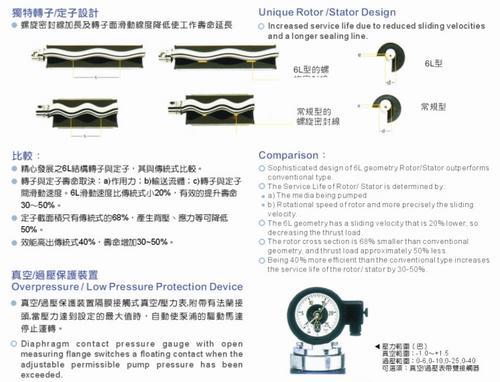

▼ 品名/編號:莫諾式單螺桿推進腔泵 Progressive Cavity Pumps |

|

>> 其他產品 |

|

![莫諾式單螺桿推進腔泵 Progressive Cavity Pumps]() |

>> 產品介紹

Seepex Pumps 產品特色:

單軸螺旋桿泵浦能平緩無脈衝地,低剪切性地輸送各種低黏度到高黏度的介質,包括含固體或不含固體顆粒的各種流體。針對較大軟質的介質,例如整塊或碎果顆粒的乳酸,能可保持的完整性。依據每位客戶的需求,提供專業設計的單螺桿泵浦,廣泛可應用在果蔬加工業,釀酒業及各種食品飲料業等等。

Seepex單螺旋(莫諾式)泵特性 Features:

1.無脈衝穩定輸送及低剪切力,不會破壞流體分子,對於敏感介質有相當的重要性。

2.因無脈衝、流量與轉速正比之兩大特性,特別適合計量或加藥設計。

3.低噪音及高效率之自吸能力。

4.輸送流體黏度可達1,000,000 cps

5.最大流量可達500 m3/hr

6.最大壓力可達48 Bars

N系列-標準工業級

CS系列-食品衛生級3-A& EHEDG 與CIP 功能\r

T系列-進料槽設計或特殊黏度流量處理

D系列-劑量或定量處理

E系列-半沉水直豎式

M系列-破碎機

Seepex (mono type) progressive cavity pump enables the transmission of all kinds of low-to-high medium, with smooth low-pulsation and low shearing, including liquids with / without solids. When conveying large and soft medium such as bulk or granule of chess, the medium remains intact. For meeting individual needs, the PC pump can be universally applied in fruit & vegetable, brewery, and food & beverage processes.

Features:

1.Steady low-pulsation pumping and low shearing ensures the integrity of components critical for sensitive media.

2.With low-pulsation and direct control of the proportion of rotation rate and capacity, gives required precision in metering and dosing.

3.Low noise output and high self-priming rate.

4.Optimum solutions for various viscosities up to 1,000,000 cps

5.Max. Capacity Up to 500 m3/hr

6.Max. Pressure Up to 48 Bars

Models:

N Group -Standard industrial use

CS Group-Sanitary 3-A & CIP Grade

T Group- Open hoppper & low fluidity design

D Group- Dosing and precise handle

E Group- Semi-Submersible pumps

M Group- Macerators |

|

|

|

|

|

|

|

|

|

公司簡介

公司簡介 聯絡資料

聯絡資料 公司地圖

公司地圖 產品與服務 (8)

產品與服務 (8)

供需資訊 (0)

供需資訊 (0) 部落格文章 (0)

部落格文章 (0)

總瀏覽人次 (25429)

總瀏覽人次 (25429)